-40%

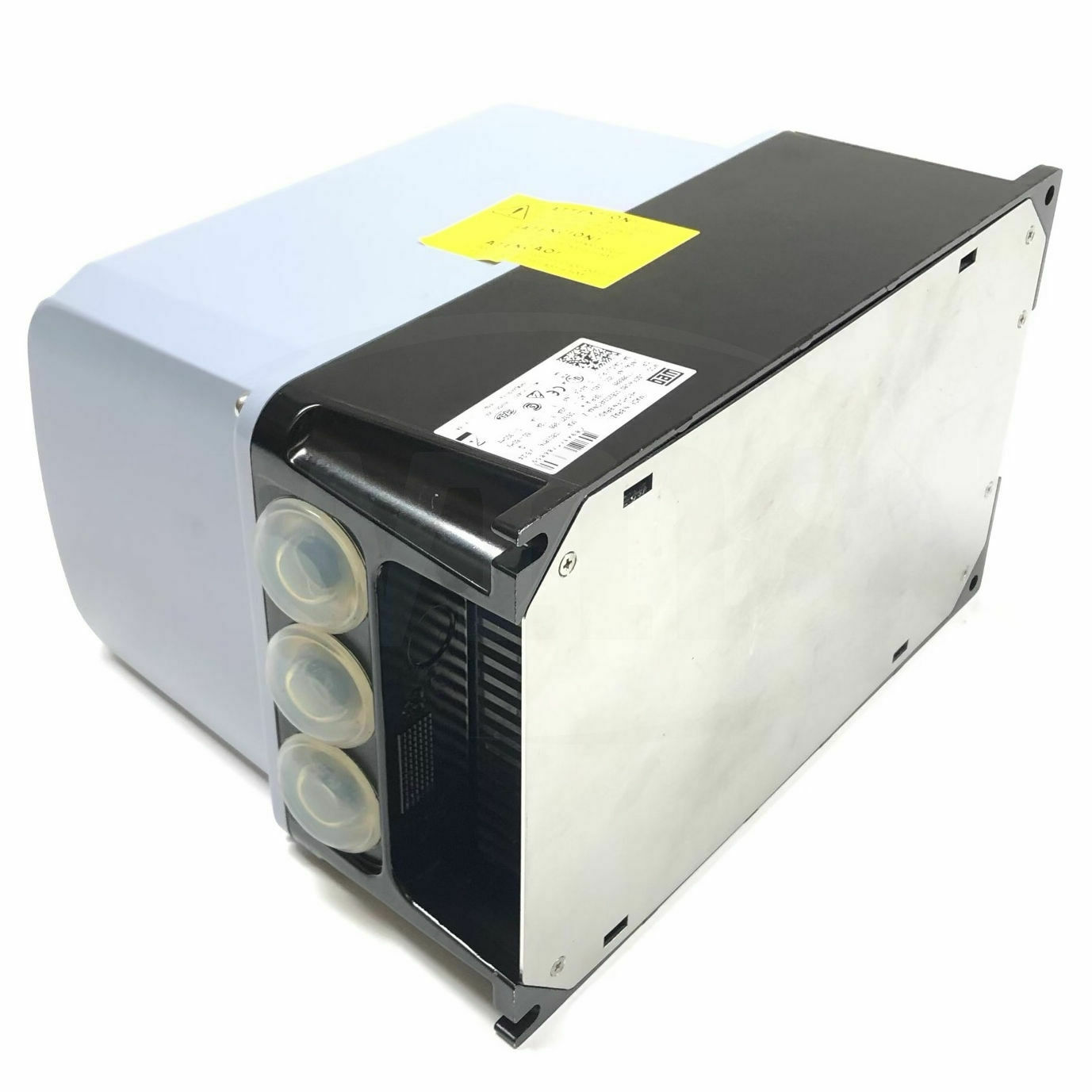

WEG CFW08 Variable Frequency Drive, 230 VAC, 10 Amps, 1 or 3 Phase, 3HP, NEMA 4X

$ 263.98

- Description

- Size Guide

Description

DescriptionThe WEG CFW08 series of drives feature the compact size of a microdrive with the full functionality of much larger drives. From extensive programmable control features to flexible mounting and display options, the CFW08 has everything one needs in a small, reliable drive package.

The WEG CFW08 WASH Series is a redesign of our successful uline VFDs. Engineering improvements have produced one of the most compact and full featured microdrives in the marketplace.

Outstanding features and options in a NEMA 4 enclosure allow the CFW08 WASH to be successfully used in a large variety of washdown applications.

Overview

Brand

WEG

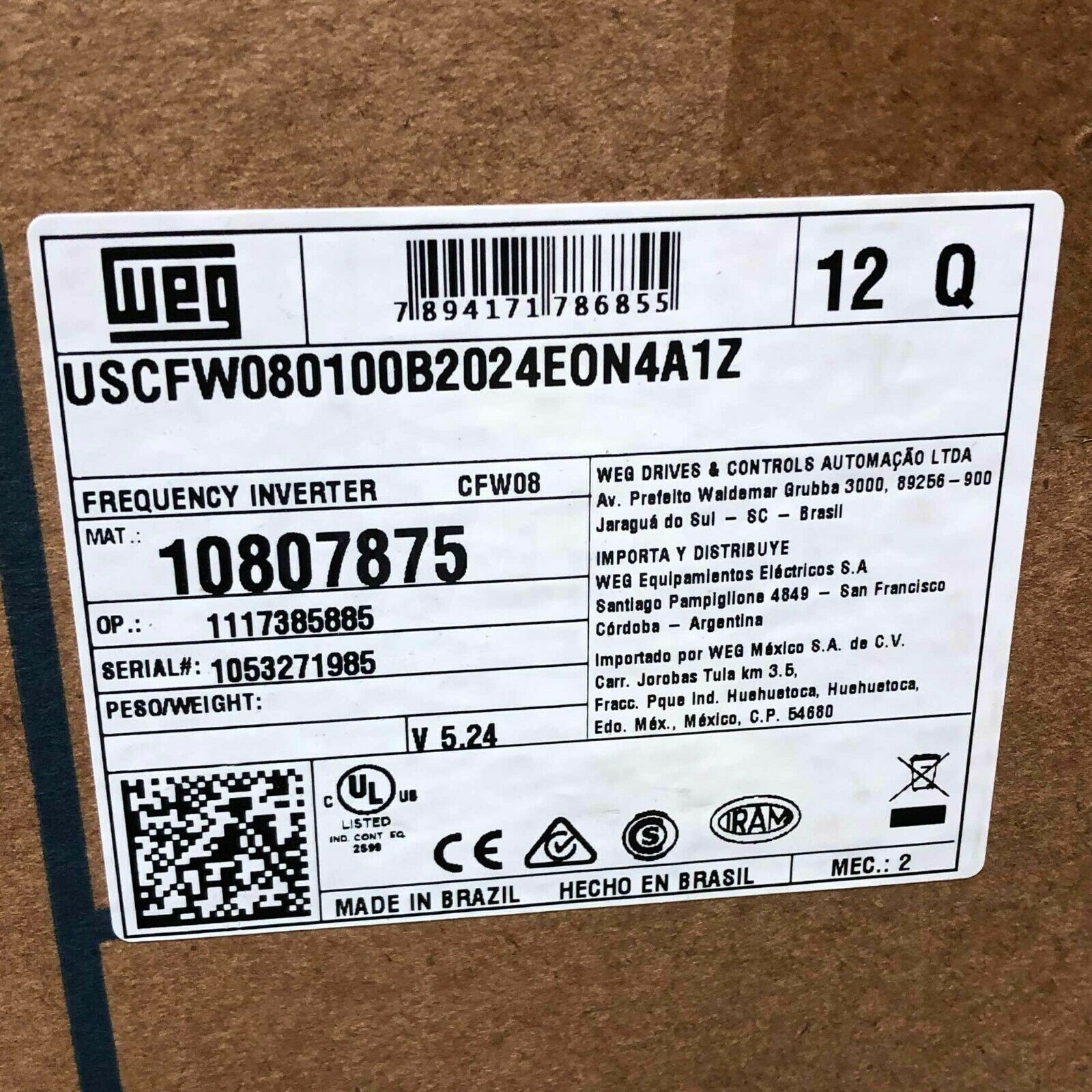

Catalog Number

CFW080100BDN4A1Z

Input Power

Three Phase - 230V

Motor

3 HP @ 230 V

Nominal Drive AMPS

10

Braking Transistor

Yes

Frame Size

A

Dimensions (H x W x D)

10.4” x 6.5“ x 8.5“

Approximate Shipping Weight

5 lbs

Enclosure

NEMA 4X

UPC

7894171786855

Standard Features

V/Hz and Sensorless Vector Control

150% current overload capacity

16 bit DSP controlled PWM output

2.5 / 5 / 10 / 15 kHz adjustable swiching frequency

Four isolated programmable digital inputs

Two programmable relay outputs (1NO, 1NC, 240VAC 0.5 Amp

Two isolated programmable analog inputs (0-10V, 0/4-20mA)

Protective features:

Over current

motor overload

drive over temperature

output phase-to-phase and phase-to-ground short circuit

DC bus over and under voltage

external fault

Control features:

Linear and "S" ramp acceleration and deceleration

local/remote control

DC braking

torque boost

motor slip compensation

electronic pot

preset speeds

adjustable V/Hz profile

maximum and minimum adjustable frequency limits

two skip frequencies

adjustable output current limit

JOG, ride-thru

flying start and PID regulator

Display readings:

Motor speed

frequency

voltage

current

last fault

heatsink temperature

drive status

Ambient: 32ºF (0ºC) to 104ºF (40ºC), 3300ft (1000m) altitude, 90% Humidity, Non-condensing

SuperDrive (G1) Compatible

Technical Data

Power Supply

Single or Three Phase 200-240V (+10% / -15%)

Frequency

50 / 60 Hz +/-2 Hz

Cos (Displacement Power Factor)

Greater than 0.98

Enclosure

NEMA 4

Control Modes

V/Hz (Scalar)

Sensorless Voltage Vector (VVW)

Power Output

Sinusoidal PWM (Space Vector Modulation)

IGBT Transistors

Switching Frequency

2.5, 5, 10 or 15kHz

Frequency Range

0-300Hz

Overload Capacity

150% during 60 seconds, once every 10 minutes

Control Inputs

4 programmable isolated digital inputes, NPN or 24VDC logic (PNP)

2 x programmable differential analog inputs, programmable for current or voltage

Can be set as DI or as PTC input (0-10V, 4-20mA or 0-20mA)

Control Outputs

2 programmable relay outputs, one NO (Form A) and one NC (Form B): 250V /0.5A

1x outputs with independent NO and NC at the same common

1x output, programmable for voltage (0-10v) or current (0-20mA or 4-20mA) and with 0.25% linearity error

Communication

Serial: Optional RS-232 Serial Interface, RS-485 with external RS-232/485 Converter

Fieldbus: Modbus RTU with external RS-232/485 Converter

Protections

Motor Over-Current

Motor Overload

Output Phase-to-Phase short circuit

Output Phase-to-ground short circuit

Programming Error

DC Link over voltage

DC link under voltage

Drive over temperature

External Fault

Ambient Temperature

32-104°F (40°C)

up to 122°F (50°C) with 2% /1.8°F (1°C) output current derating

Humidity

5-90% Non Condensing

Altitude

0-3300ft (1000m)

up to 13,200ft (4000m) with 10% /3300ft (1000m) output derating

Regulatory Conformance

EMC Directive 89 / 336 / EEC

ENC61800-3

LVD 73/23/EEC

UL508C

Special Functions

Linear and “S” ramp accel and decel

local/remote control

FWD/REV selection

DC braking

manual and auto torque boost

motor slip compensation

electronic pot

two skip frequencies

maximum and minimum adjustable frequency limits

adjustable output current

PID Controller

Keypad

4 Digit display

2 indicator LEDs

8 keys

Keypad Readouts

output frequency (Hz)

output current (A)

output voltage (V)

motor torque (%) in vector mode

DC bus voltage (V)

value proportional to frequency

heatsink temperature

fault

status messages

Mounting

Surface Mounting with Screws

Applications

Pumps

Fans

Blowers

Conveyors

Rollout Tables

Agitators

Mixers

Any Washdown Applications

About this Product

Main Characteristics

Output current from 1.0 to 33 A (0.25 to 20 cv)

Single or three-phase power supply

Supply voltage from 200 to 480 V1)

Vector (VVC) or scalar (V/F) control

Accessories to expand functionalities

Standard, Plus or Wash Versions (IP66/NEMA 4x)

Multipump control

Built-in operating and programming interface (HMI)

Brake IGBT

Internal (optional) or external (accessory) RFI filter

Fault or alarm diagnosis

Optional items for CANopen, DeviceNet, RS485 and RS232 industrial communication networks

Remote operating interface - HMI (optional)

Free SuperDrive programming software

Applications

Multimotors and multipumps

Centrifugal pumps

Process dosing pumps

Fans / exhausters

Stirrers / mixers

Extruders

Conveyor belts

Roller tables

Granulators / pelletizers

Dryers / rotary ovens

Rotary filters

Winding machines / uncoiling machines

Cutting and welding machines

Special Functions and Resources

Password to enable programming

Fault self-diagnosis and auto-reset

Indication of specific quantity (programmable) - (e.g.: m/min, rpm, among others)

Slip compensation (V/F control)

Adjustable quadratic and linear V/F curve

Self-tuning routine (sensorless vector control)

Dynamic braking

Momentary speed impulse function (Jog)

Copy of the setting via serial operating interface - HMI (copy function)

Linear and “S” type ramps

Independent acceleration and deceleration ramps

DC braking (direct current)

Multispeed function with up to 8 preset speeds

Selection of the direction of rotation

Overlapped PID control (automatic control of level, pressure, etc.)

Start with the motor spinning (flying start)

Rejection of critical or resonant frequencies (skip frequency)

Operation during momentary network faults (ride-through)

Communication protocols: Modbus-RTU, CANopen and DeviceNet

Multipump Control

The CFW08 version with multipump control board (A5 in the control board option in item 9 of the smart code) can control up to 4 pumps at the same time, keeping the output pressure constant, regardless of the flow demand. The CFW08 with multipump control board can also monitor the suction pressure and the source reservoir level, in addition to enabling the smart drive of the auxiliary pumps based on the running time.

Connectivity

Especially designed to integrate large industrial automation plants, the Fieldbus industrial communication networks provide advantages in the supervision, monitoring and control, generating high performance and great operating flexibility - ideal for applications on complex or integrated systems. The CFW08 can be interconnected to the industrial networks with worldwide used protocols: CANopen, DeviceNet, Modbus-RTU and Profibus-DP.

a